Single Screw Extruder Knowledge Part 4-Gear box

Single Screw Extruder Knowledge-Part 4

The drive system of the extruder is to provide the extruder with the power to operate the screw. In order to meet the requirements of the extrusion process, the power of the extruder should have the following requirements:

1) The screw can have enough torque.

2) The screw can start from a low speed, then stepless speed regulation to the required speed, and should be constant rotation

Moment state.

3) Smooth operation and no fluctuation in speed.

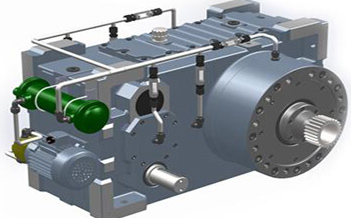

The transmission system is mainly composed of an electric motor, a continuously variable transmission and a speed reducer. Since the high-power continuously variable transmission is difficult to manufacture and the efficiency is low, the extruder generally selects a variable speed motor, and can simultaneously function as a power source and a continuously variable transmission.

The reducer of the extruder is to reduce the output speed of the motor to meet the screw speed

It is usually used with pulleys and gear reduction gearboxes. In some extruder designs, there is no pulley between the motor and the reducer. The wheel has three functions

1) As the first stage of deceleration, reduce the reduction ratio of the gear reducer.

2) When using a three-phase AC commutator motor with a gear ratio of 1:3, it can be replaced by a pulley

The way to expand the gear ratio.

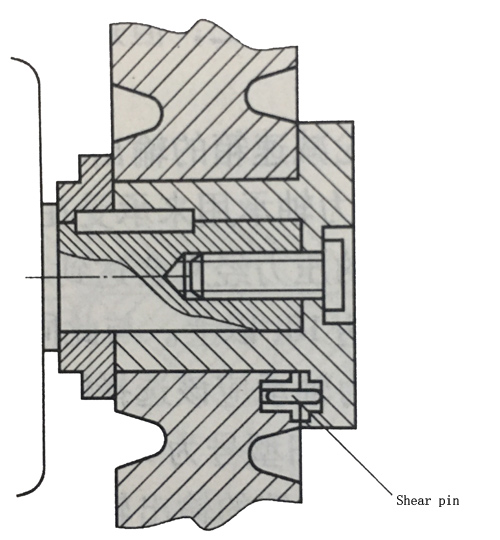

3) Belt drive can provide certain overload protection. When the screw torque is too large, the belt will slip.

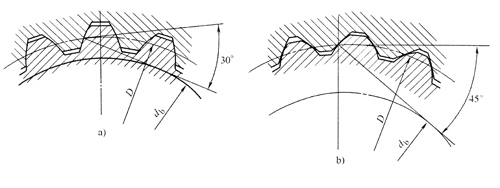

Protect the extruder from damage. Of course, the protection of this method is very limited, generally the larger size of the extruder will be additionally equipped with mechanical protection(As above drawing shows) and electrical protection devices.

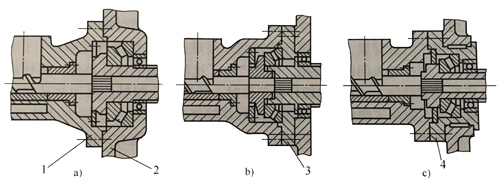

a.feeding seat connect directly to gear box b.Middle plate structure c.Middle sleeve structure

The planetary cycloid gear reducer and gear reducer are commonly used in extruders. The planetary cycloidal gearbox has the advantages of large speed ratio and small volume. In the application, the planetary cycloidal gearbox is often driven by the motor to design a very compact extruder. The small extruder can also use a worm gear reducer. The worm gear reducer has a large speed ratio and has a 90° steering. There are more options for the extruder design. But due to planetary cycloidal teeth

a.Outer Spline b.Inner Spline

Drawings of spline connect the screw and gear box

Wheel reducer and worm gear reducer have little power, so generally only meet the requirements of small extruders. Most extruders also use gear reduction gearboxes. At present, the gear reducer for the extruder is mostly a special gear reducer. The so-called special purpose is to design the position of the thrust bearing on the gear reducer case. Of course, it is also possible to use a universal reduction box in the middle plate or the intermediate sleeve to achieve the purpose.

NEXT part we will learn the style of extruder, say single screw extruder and twin screw extruder.

For more information on Fusion-Plastech plastic sheets extrusion line, pls click www.fusion-plastech.com. Cell/Whatsapp: +86 18661986585, Email: [email protected].

- About Us

- Company Introduction

- Contact Us

[email protected]

[email protected] gongsong2010

gongsong2010 +86 18661986585

+86 18661986585